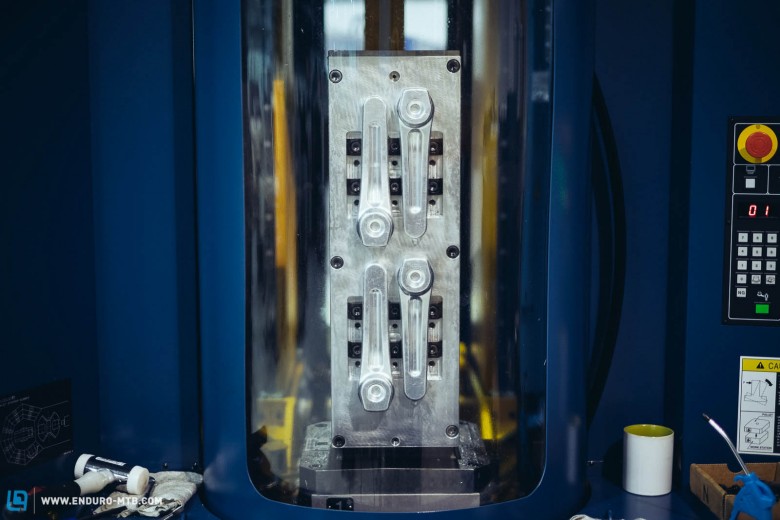

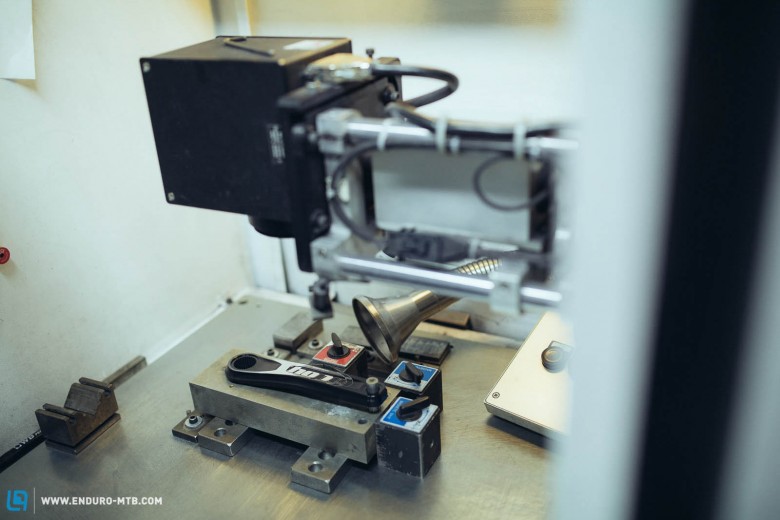

We have been eagerly anticipating the arrival of Hope’s first set of cranks. For years they have been producing prototypes and testing, now we know why. In this video and photo story, You’ll get an in-depth look at the attention the detail that goes into each step of the process from design to installation. It is clear that Hope didn’t just produce another crank for the sake of expanding their product line. They really made sure to provide clear benefits, bombproof construction and of course, the raw beauty of machined aluminum that is typical of the UK brand.

Check out our own factory visit and the first look for more info on the cranks.

Photos: Duncan Philpott

Did you enjoy this article? If so, we would be stoked if you decide to support us with a monthly contribution. By becoming a supporter of ENDURO, you will help secure a sustainable future for high-quality mountain bike journalism. Click here to learn more.