Exclusive | SRAM Announce New Guide Ultimate Brake

Last year SRAM announced the new Guide platform, providing a powerful brake for the enduro and trail markets, with the SRAM GUIDE RSC headlining the range. SRAM wanted to take things further – building on the Guide platform to produce the ultimate brake.

With a redesigned caliper SRAM have made the Guide platform significantly more effective, and named it the ‘Guide Ultimate‘. This brake has already been tested (in a disguised format) under the hands of many elite athletes and has already won Enduro World Series rounds (Jerome raced a set to victory last weekend), Marathon Worlds and WC DH races. Finally the cat’s out of the bag and we can tell you all about it.

Previous generations of ‘Ultimate‘ brakes have all been about saving weight – and with a carbon fibre blade and titanium hardware the new Guide Ultimate comes in at just 360 g. But SRAM admit that the new brake is about more than just ‘lightweight’, it features some entirely new engineering concepts, and new technology.

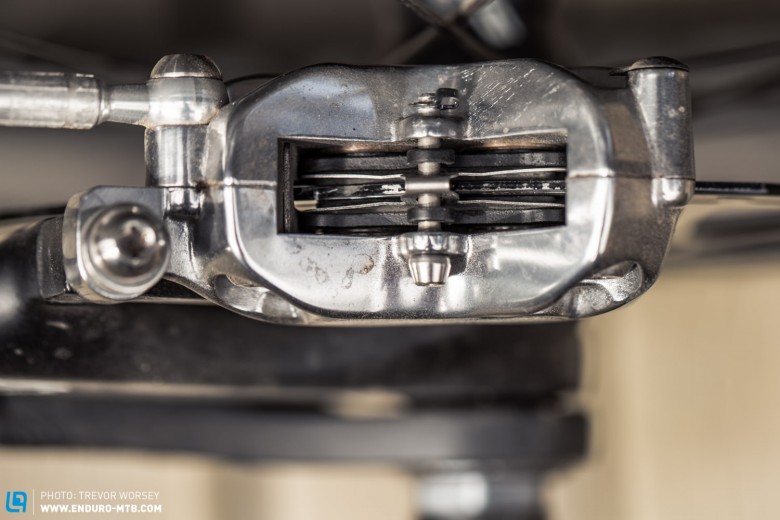

The Guide Ultimate features a similar lever as the current Guide, but with a new carbon fibre lever blade with titanium hardware. The SwingLink lever cam ensures modulation is high and the use of bearings in the pivot result in a smooth and precise lever action. The same large reservoir and high fluid content remains, ensuring that the brake requires minimal attention when it comes to bleeding. However, it is the new S4 caliper where most of the changes can be found. This is a completely new caliper that features some new technology.

The first innovation is the use of new aluminium pistons (in place of the phenolic plastic pistons), by machining a highly accurate ribbed surface, SRAM can precisely control the amount of seal and fluid in contact with the piston and ensure very consistent activation. SRAM have also added a new seal, which has a new design to help control the speed of the roll back (how fast and far the pistons pull back into the caliper). On the trail this means that the bite point and feel of the brake will be the same regardless of temperature.

To improve the heat management of the brake, SRAM have added three new technologies. The first being a phenolic plastic core on the inside of the new aluminium pistons. This insulator sits in between the piston and the hot backing plate, ensuring temperature transfer is kept to a minimum. The next thing was to develop a heat shield that sits in between the hot edge of the backing plate and the inside of the caliper. The small stainless steel plate interrupts the thermal flow, and provides a 20 °C reduction in fluid temperature. The final change was to open up the pad pocket of the caliper by 2 mm, by keeping the pads open their entire length this really helps air flow through the pad. The overall result of these changes is that the current guide brake runs at 220 °C, the new Guide Ultimate runs at 194 °C (just 1 °C higher than the class leading Shimano brakes with Ice Tech rotors).

Guide‘s have always been promoted as requiring minimal maintenance, with large fluid reservoirs to minimise the impact of air in the system and long bleed intervals. SRAM wanted the new Guide Ultimate to be as easy to live with as possible and have made some changes – introducing the ‘Bleeding Edge‘ technology. The first is to redesign the porting on the inside of the caliper, allowing for a true bottom up bleed which makes a field bleed a lot easier. What we were most impressed with however is a new ‘lossless‘ adaptor, one end plugs into a syringe and the other plugs into the caliper. The adaptor features an open/close connector which makes bleeding a breeze, no more messing with spanners and fluid all over the place. This is certainly the simplest method of bleeding brakes on the market, and the adaptor will be included with each brake set, and with bikes fitted with Guide Ultimate brakes.

To go with the new brakes, SRAM have also included a new two piece rotor based on the centreline rotor, saving 10 g on the 160 mm rotor, and 20 g for the 180 mm. These will be available in both 6 bolt and centre lock patterns and in black. This new lightweight rotor brings the all up weight package to 360 g (for a front brake with a 900 mm hose).

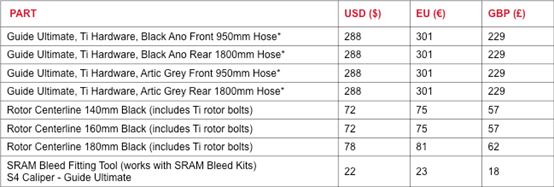

Pricing

First riding impressions

We were offered the opportunity to get a sneak peek at the new Guide Ultimate brakes on the fast and technical trails of Rotorua NZ. First impressions would suggest that SRAM have done a great job – after a day of hard riding we were very impressed with the feel of the brake and the powerful, noiseless performance.

The bite point was incredibly predictable and the brake was very easy to modulate. Working through the range of adjustments on the brake (contact point and reach), no matter if you prefer a long lever throw or an immediate bite point – it was exceptionally easy to set them up just as you like. The lever feel is still class leading in the market, with the pivot bearings providing an impressively smooth action. We are keen to get these brakes in to the Alps to see how they perform in high temperature applications.

Words: Trev Worsey

Photos: Trev Worsey & Adrian Marcoux

Did you enjoy this article? If so, we would be stoked if you decide to support us with a monthly contribution. By becoming a supporter of ENDURO, you will help secure a sustainable future for high-quality mountain bike journalism. Click here to learn more.