Do you like high end components on your mountain bike? Do you like riding at the top of your game? If so, you should definitely check out what Colorado based shock tuner PUSH Industries has to offer.

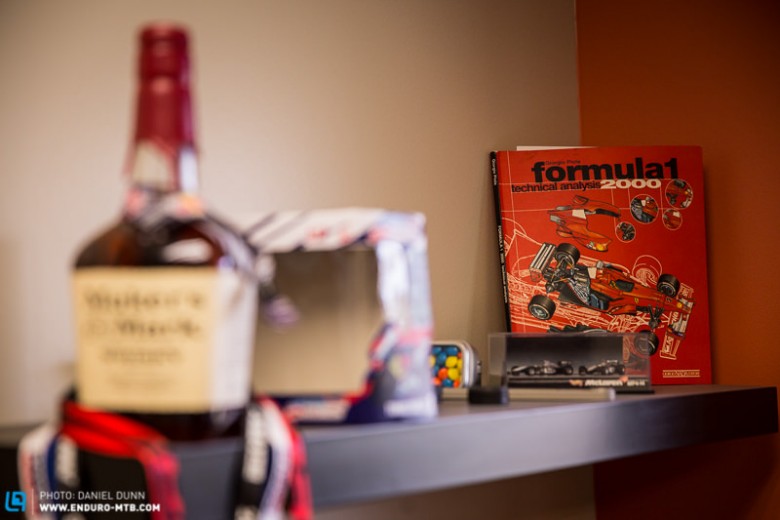

PUSH Industries is a small shock tuning and production company based in Loveland, Colorado. Started in Irvine, California by Darren Murphy, who worked his way up and through the suspension divisions of auto and motorcycle racing teams, eventually finding himself in the world of mountain bikes, and starting his own company. Growing up enjoying motorcycles and car racing, those long held personality traits influence everything he does in the mountain biking world. I’m talking about the use of high end materials, ultra tight tolerances, and commitment to building the best possible product.

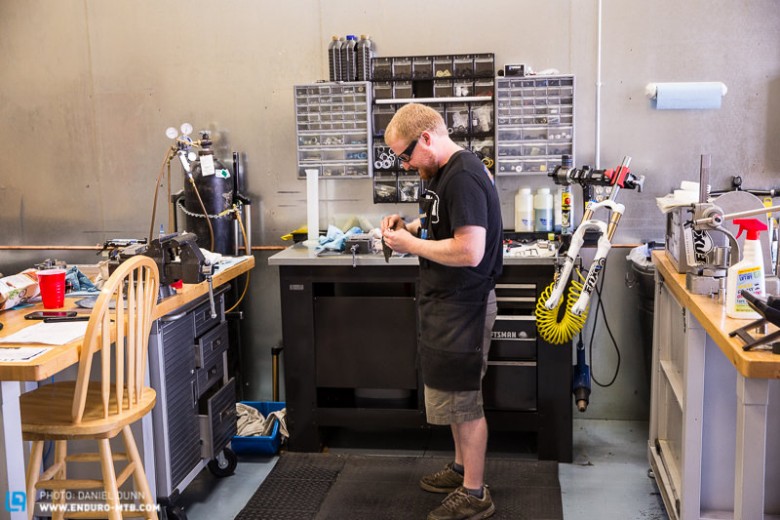

PUSH is a cool company for many reasons. They’re small. On the day I visited, about eight or nine employees, including Murphy, were going about their work. They all ride. A lot. So they know what their product can do for you and how it can improve your ride. They’re dedicated to producing the best possible product they can. That involves using the best raw materials, taking their time when shaping those raw materials, and partnering up with other companies that share that same respect for producing the best, like Hyperco Springs (These guys build arguably the best suspension springs on the planet for the auto racing industry, having multiple champions in NASCAR, Formula One, and the Indy Racing League.)

PUSH has moved on from just tuning forks and shocks into building their own product from scratch, the 11/6 coil shock for longer travel trail bikes. The culmination of years of tuning experience, learning from what customers wanted and what they asked for, and realizing the market was ready for it, Murphy designed the 11/6 for the most discriminating of riders. Each and every shock is custom built for that particular bike, and for that particular rider. Every component of the shock serves it’s purpose, and that is to glue your bike to the ground, in the most responsive, but comfortable way possible. As Murphy is fond of saying, “more grip”. These shocks are high quality, and the price reflects it ($1200 retail). PUSH knows they won’t sell a million of these shocks, and they don’t want to. They want to build top notch quality, for the discerning rider.

For more information check-out: pushindustries.com.

Words & Pictures: Daniel Dunn

Did you enjoy this article? If so, we would be stoked if you decide to support us with a monthly contribution. By becoming a supporter of ENDURO, you will help secure a sustainable future for high-quality mountain bike journalism. Click here to learn more.