With most bikes in these globalised times being produced in the Far East, it took some searching before we arrived at a farmyard in the middle of nowhere to observe some genuine artisanal bike production in action. Take a look behind the scenes of NICOLAI.

In these times of throwaway goods and rapid consumerism, it’s pretty telling that even marketing hype now shies away from declaring that they’ve created a product “for life.” These days we’re after a quick fix, a shot of dopamine for a budget-conscious purchase, and it’s the same story from the supermarket aisle to bike-shop browsing. Aluminium was once ‘the new steel,’ and now carbon is the new aluminium. The fascination with carbon is huge, but it’s also unfortunately no more than hazardous waste. We can’t change that, but there is still a ray of hope.

I’m fifty now, and I want to focus on doing things that make me happy – which happens to be bike development. Kalle

It’s 8 am as we finally enter that 134-year-old farmyard, having twice driven right by the entrance to find ourselves once more in a German hinterland of fields, marshes, and woodland. We’re at the HQ of NICOLAI GmbH in Lübbrechtsen, one of Germany’s oldest villages, now just home to 160 residents. In a strange way, the old farm emits a striking yet somewhat disgruntled demeanour. The absence of cows and tractors is disarming, and you half-expect to see a corpse lying amongst hay bales. It certainly isn’t the sort of place you’d associate with one of the cycling industry’s most innovative and radical-thinking bike manufacturers in Europe. In the same manner as Steve Jobs, NICOLAI founder Karlheinz Nicolai, aka Kalle, also cut his teeth shaking up the industry’s status quo in his garage. In Jobs’ case it ushered in a new computer era, whereas Kalle sparked a mountain bike revolution. His creations have won Downhill World Championship titles, he’s behind the first dirt bikes and mountain bikes with belt drives, and just three years ago developed a geometry concept that’s still right on the radical pulse of the times.

In modern geometry terms, ‘long’ for a size L frame means a head angle below 65° and a reach of 470 mm. But go back three years and those stats were miles removed from the norm. That’s when NICOLAI introduced their GeoMetron concept along with Mojo Suspension UK, and it confounded the industry, redefining the term ‘long’. It led to furious head scratching for some, demonstrating how the brand were years ahead of their time. But how times have changed; right now there’s no argument against the suitability of geometries with downhill-worthy head angles and 550 mm-plus reaches on trail and enduro bikes.

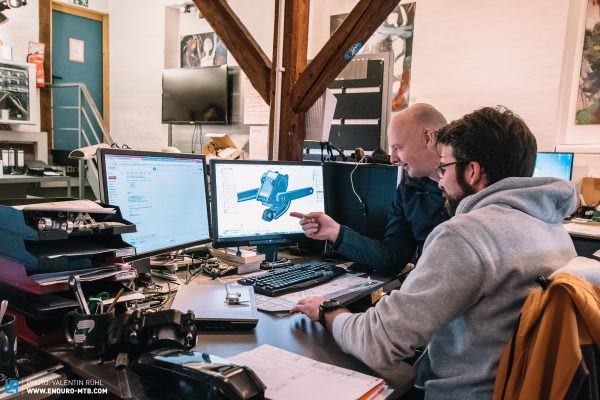

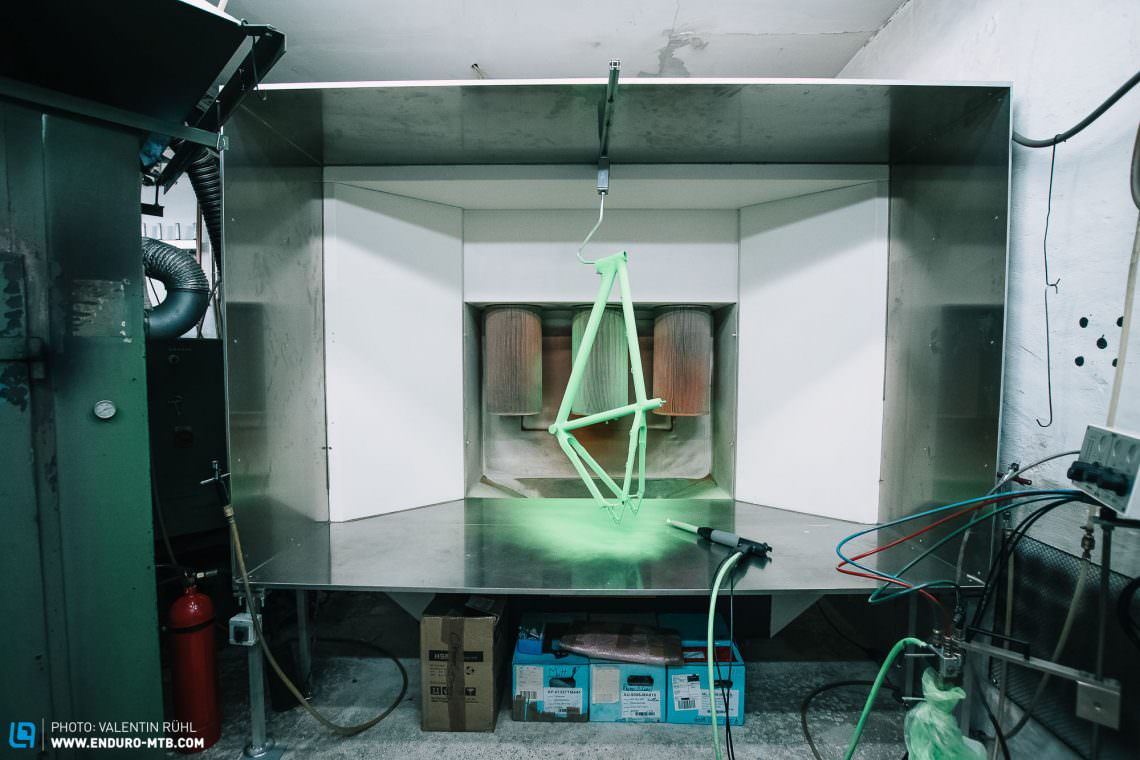

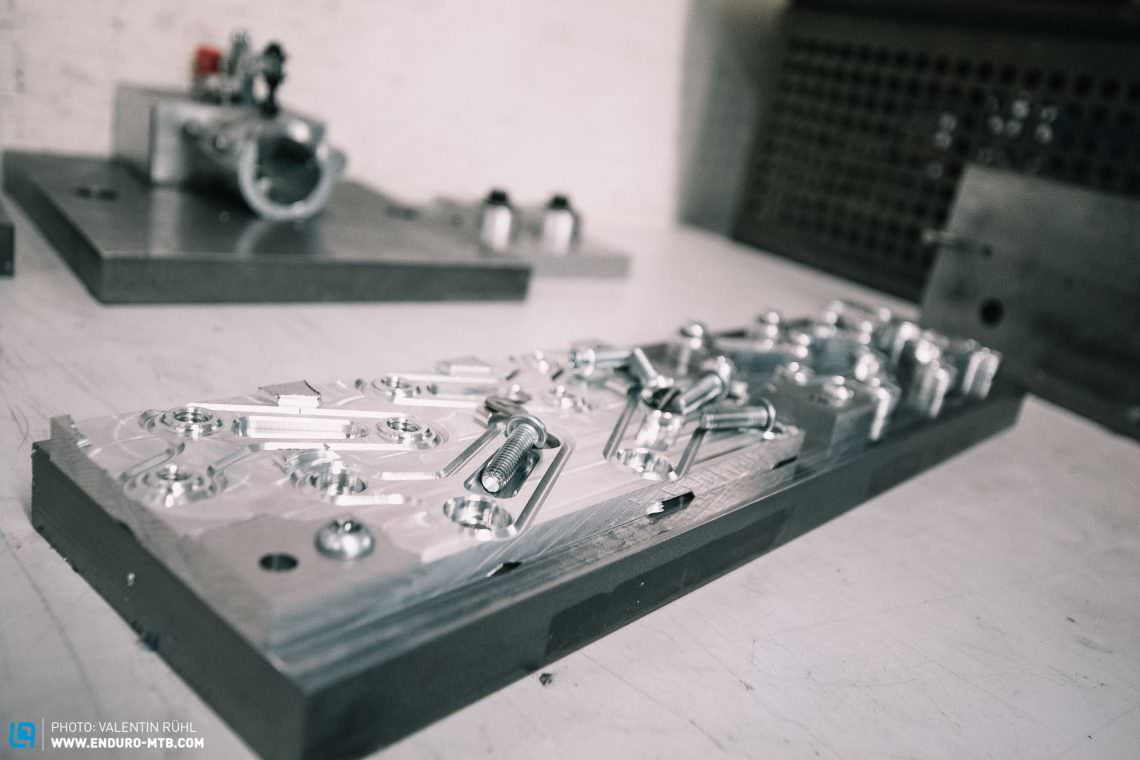

Reaching the pinnacle of the industry doesn’t mean jumping onto every trend, which is why NICOLAI has consciously skirted around carbon. In their eyes, there’s still a lot of scope for potential for aluminium. Pairing high-tech modern methodologies with tradition and a real love for engineering, their unconventional recipe lends itself to a distinctive brand image. While the farmhouse can tell some stories from its exterior, there’s a lot going on inside with CNC milling machines working alongside skilled welders, bikes being assembled by hand, and developers putting final finishes to paint jobs. ‘All done in-house’ clearly applies here. In total NICOLAS counts twenty employees on a day-to-day basis, and innovation appears to be in every detail. We watch tubes being masterfully and lovingly welded, adding to the brand’s already strong reputation for these pieces of art. Powder coating and paint jobs in all manner of colours are carried out with the same finesse that floods into the brand’s nothing’s-too-much service approach for clients. Should an issue arise with a NICOLAI bike, then you’re not just welcomed, but encouraged to bring it directly to HQ for immediate servicing. Often riders come back to the brand with bikes that are already over a decade old, which speaks volumes for their durability – and it should. After all, NICOLAI strive to make bikes for life.

It’s a brand that’s pulling out innovation from tradition. In touch with its roots, it chooses not to wallow in the past but continue a dogged pursuit towards progress. They’re still committed to conventional mountain bikes, and we caught glimpses of exciting developments in the pipeline. Coincidentally, NICOLAI are also shifting locations, hauling their wares out of the farm shortly after our visit and settling into a more modern warehouse. But regardless of what state their HQ is in, we’re stoked to see what visionary products they’ll launch in the future.

Nice one, Kalle! NICOLAI proves that quality – despite globalisation and consumerism – is still worth more than its price tag.

Fore more info head to: nicolai-bicycles.com

This article is from ENDURO issue #036

ENDURO Mountainbike Magazine is published in a digital app format in both English and German. Download the app for iOS or Android to read all articles on your tablet or smartphone. 100% free!

Did you enjoy this article? If so, we would be stoked if you decide to support us with a monthly contribution. By becoming a supporter of ENDURO, you will help secure a sustainable future for high-quality mountain bike journalism. Click here to learn more.

Words & Photos: