On Location | A Walk Around Hope Technology

If you love mountain biking, when it comes to the bucket list, some things are a must. The list is long, chatting with Peaty, ride the Alps, race the Mega Avalanche, go to Whistler, etc, etc, but when it comes to factory visits, Hope is the top choice. So was excited to find myself starting the 2½-hour trip at daft o’clock in the morning on route to Hope Technology.

I had visited the old site back in the late 90’s and it was impressive then, but had more of a ‘just an engineering factory’ feel. I knew it was somewhat more impressive nowadays, and I could see straight away on arrival at the huge factory in the middle of the small UK northern town of Barnoldswick, they had definitely moved onwards and upwards.

[banner]

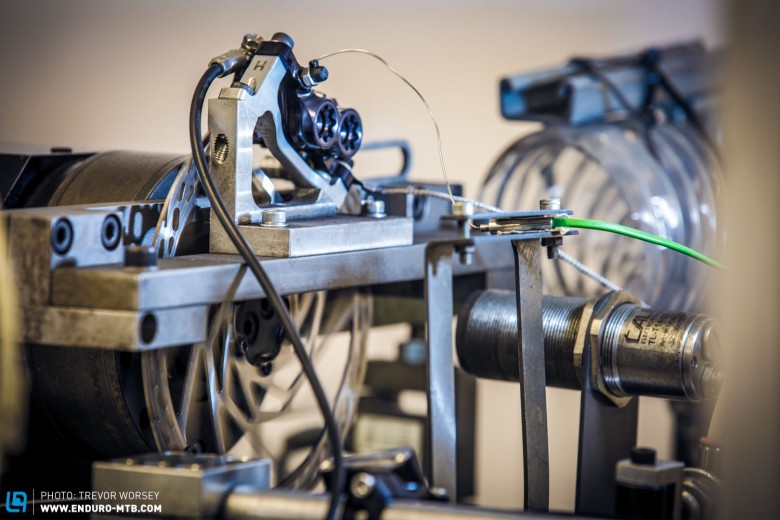

We were there to run a brake group test, as Hope had all the kit we would need to accurately test the performance of the leading brake models. I was also joined by our long term tester and ‘engineer by trade’ Coop, he was chuffed to bits to check the place out. Rachael Walker met us at the door, she is in marketing and a smiley nice lass, often the one to sort all this kind of stuff out with a welcoming smile. Also one of the top managers Allan, brother to co-owner Ian Weatherill was on hand for the first tour. Ian has been involved with Hope virtually from the start and always used to sort our brakes out at the Hope pits during the 90’s at the races, plus he was no stranger to the odd DH race back in the day.

Ian Wetherill and Simon Sharp were trials riding mates and mountain bikers way back in the late 80’s, and after deciding that mountain bike brakes were crap, they went about making one of the first sets of MTB discs brakes in the world. As Engineers they started producing a few MTB things alongside their normal work, and as demand gradually built up they had to concentrate on the development of a global brand full time, a brand that is thriving over two decades later. Hope now employs well over 100 staff, with plans of an even bigger and brighter future for the company.

[caption id="attachment_71507" align="alignnone" width="780"] There’s some great retro rigs to be seen in the entrance hall

There’s some great retro rigs to be seen in the entrance hallOn arrival into the ground floor entrance, you are immediately impressed with the display of historical bikes dotted here and there, kids experimental bikes, one of the original Pace DH bikes, an old Cannondale, even retro trials motorbikes, all in pristine condition, each sporting past production pieces by Hope. Up the stainless gripper sheeted stairs and you get to the main foyer, yet again another impressively large room, adorned with more bikes, clothing and a display of the latest Hope products and of course a huge Christmas tree!

The one thing that strikes me about this part of Yorkshire is how soft spoken and generally friendly the folk are, all greet with a sincere welcome. Onwards and we are taken from room to room to see what goes on, we are already blown away just by the amount of offices. There are rooms where things are designed, graphics rooms (they now make all their own) a marketing room, photographic studio, the list goes on and on. We then get a quick brew in the games room before the main tour begins, it is time to check out the engineering floor. But before we head downstairs, we take in the games room, not only is there a pool table with a custom printed silver Hope logo cloth, but also a full size snooker table, I mean how many people have one of those in the tea room?! Also in this room is the extremely trick looking road bike ridden by Martyn Ashton in ‘Road Bike Party’, this thing is impressive, but it was with a heavy heart I admired it.

We chatted with the two owners for a while, these guys love Hope and their jobs, choosing not to sit back on the profits in Barbados, vowing never to sell out to some faceless corporate machine. These guys come in each and every working day, and both still love their riding. Simon (a true racer) talks excitedly of his plans for 2015 and the epic races he will compete in globally. I’ve raced with Simon and believe me he rips, usually posting the fastest Super Vets times, no stranger to speed and bike skills. The ambition and creativity of these guys is obvious, Ian tells us of how they are now building a structure, which is to double up as a velodrome and their new carbon fibre factory, wow!

Next up we’re taken straight outside to check out some work in the making, the coolest looking pump track, made by a world pro rider and currently being continued by a local, who’s been working on it for a few more months, The Weatherills laugh as they proudly tell us how they have way-exceeded the budget on this already! Down near the bottom of this track is a purpose-built chill-out area, sound system; comfy chairs, huge canopy, the lot. Now I’m overcome with one thought, ‘these boys really don’t do things by halves’. Back inside and the shop floor of the factory begins.

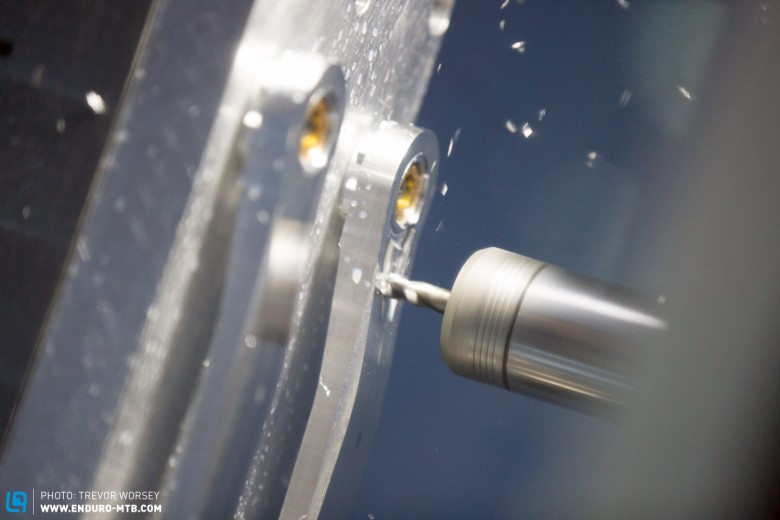

This time we are shown round by Sam Gibbs, when we ask him his job title, he replies “I just kind of do everything” brilliant! There are workers everywhere, all busy doing their part of the large Hope jigsaw. I’m blown away by just how many expensive machines there are, money being constantly invested back in to Hope’s future. Machinery is just flat out everywhere, milling, drilling and cutting, I looked at Coop’s massive smile and he laughs when I say this must be like an engineers wet dream!

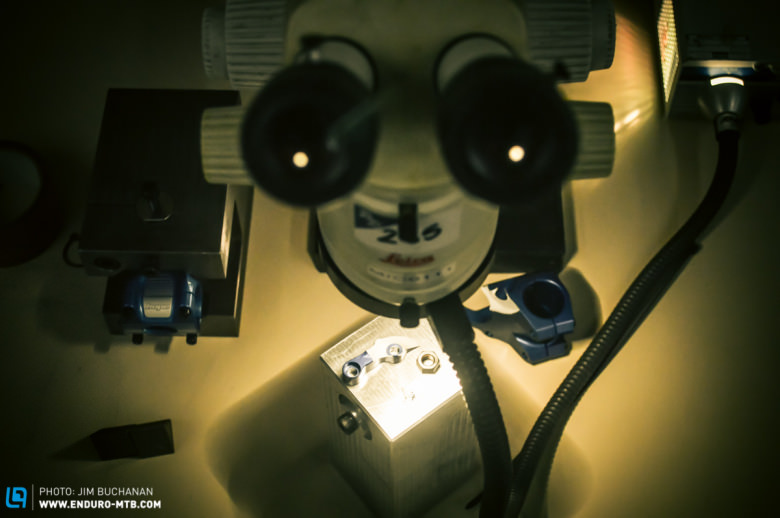

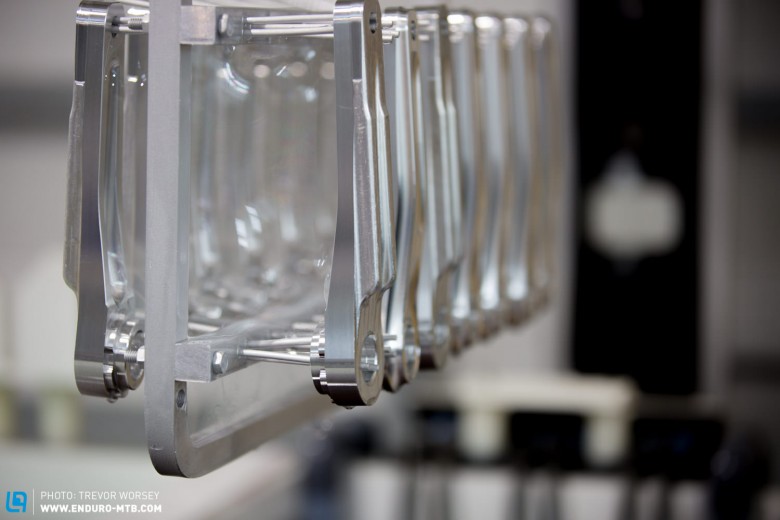

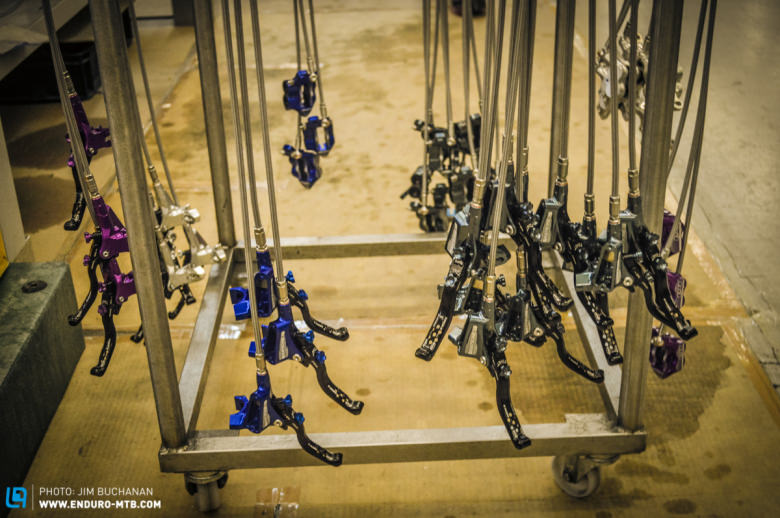

Parts and products are everywhere, there seems to be a room for everything. We check out the measurements room where finished products are inspected, there’s a huge anodizing room, a room where things are tested to destruction. There’s a wheel building room, some started by a machine, but all checked by hand before being shipped off to their various destinations. We are given a demo in the brake bleeding area, shown a very quiet warranty room, a hub construction area, a very impressive laser cutting disc area, then there’s the places where they make bars, stems, headsets, BB’s, grips, holy shit, it’s almost too much to take in. I can tell Coop is seriously impressed with this place, as he chats to loads of the machine operators using terms so foreign to me I was just baffled with their tech talk, so here is Andy’s take in it as an engineer.

“As an engineer I was really impressed with how Hope operate, many disc manufactures punch their discs out of sheet metal, which is quicker and so cheaper, however this puts stresses in the material which make them more likely to bend or warp while riding. For this reason hope laser cut their discs, which avoids adding these stresses, even though this makes it slower to manufacture, a better end product is produced. Also I was really impressed with the anodizing process, Hope do all their anodizing in house to strictly control the time in the caustic soda bath and they even machine some of the components to a slightly larger tolerance, so that they’re perfect after anodizing.

“The biggest benefit of keeping it all in house is that the machining facility at Hope is very flexible, for example the machine setter can change the part in the machine from a brake lever to a brake caliper in a matter of minutes. This means that the majority of parts are actually made to order, vastly reducing the large amounts of space needed for stock and also to improve working capital, all meaning cheaper parts for us!

This is a manufacturing system adopted from the automotive industry. Inspection is also very important at Hope, they manufacture a lot of components with bearings in them, where tight tolerances are crucial, and to ensure they are correct they check every part. Not all of this is down to good machinery and clever processes but also the employees, you can have the best quality system in the world but if the employees dislike the company, then scrap will still go out the door. Everyone I met at hope generally cares about the company, they all have pride in the work and highly value Hope’s reputation, and this is now very rare in a UK company.”

Something clearly noticeable when touring the factory is the ridiculous amount of new, high-end bikes adorning the factory’s walls and corridors. We are told how there are around 150 of them, most are bought in (some donated by manufacturers) most come in as frame, forks and gears, then are stripped of all decals and livered up in the Hope colours and fitted with every conceivable Hope product. The policy at Hope with bikes is that no employee ever buys a bike, all are given a company bike to suit their needs, so they never want for anything, just how cool is that!

Now of late I have been a bit of a pessimist when it comes to the demise of British industry, the average working tradesmen is often seeming at the end of their tether with the onset of EU rules, cost cutting, faceless corporations, mergers and work outsourced overseas; where the workers aren’t boxed into a corner by the constant ramblings of the health and safety police. I just imagined that the engineering side of the UK would also be suffering with this type of clock-watching boss-hating attitude. Having worked in large factories myself, I have experienced this first hand. But oh no, this was like a massive breath of fresh air, the employees love their jobs at Hope and are very proud to do what they do; this is a real testament to what happens if you look after your staff and build up such a fantastically impressive UK company. After our visit was over Hope gave me a feeling I hadn’t experienced in years, I was proud to be British!

Big thanks to Hope for the tour and very wet Christmas night ride and great works meal.

Words by Jim Buchanan & Andy Cooper Photos: Trev Worsey & Jim Buchanan

Did you enjoy this article? If so, we would be stoked if you decide to support us with a monthly contribution. By becoming a supporter of ENDURO, you will help secure a sustainable future for high-quality mountain bike journalism. Click here to learn more.