Robot Bike R160, Is this the worlds best mountain bike?

For generations bike design has enjoyed radical but still incremental growth, small changes bringing new innovation and fresh perspectives. Until now designs have not deviated too far from conventional materials, instead focusing more on changes in geometry and drivetrain. But what would happen if designers more used to dealing with F1 and the aerospace industry took it upon themselves to build the ultimate bike? Now you can find out, welcome to the Robot Bike Company R160.

The team behind Robot Bike have taken a totally new approach, engineering lightweight frames that are unique to each and every customer. Drawing from their experience in the world of aerospace and F1 and working in partnership with suspension supremo Dave Weagle, the team have come up with a very interesting product.

What’s so special about the new R160

The 160 mm R160 is Robot Bike Company’s first frame, and it looks radically different from everything else on the market. Uniquely each R160 frame is configured to a customer’s exacting specifications, but this process does not come cheap at £4395. Robot Bike gathers the customer’s specifications and measurements, then suggest a geometry that will best meet the customers specifications. Then in partnership with design company HiETA’s CAD and simulation tools output a design in an automated process. “It doesn’t matter how good a frame is if it doesn’t fit the rider, and this is where Robot Bike Co. sees the weakness in the current market offerings” Says Robot Bike’s Ed Haythornthwaite, “If you are trying to produce the very best frame it makes no sense to then only offer it in a small number of sizes when the people you are selling it to come in all shapes and sizes.”

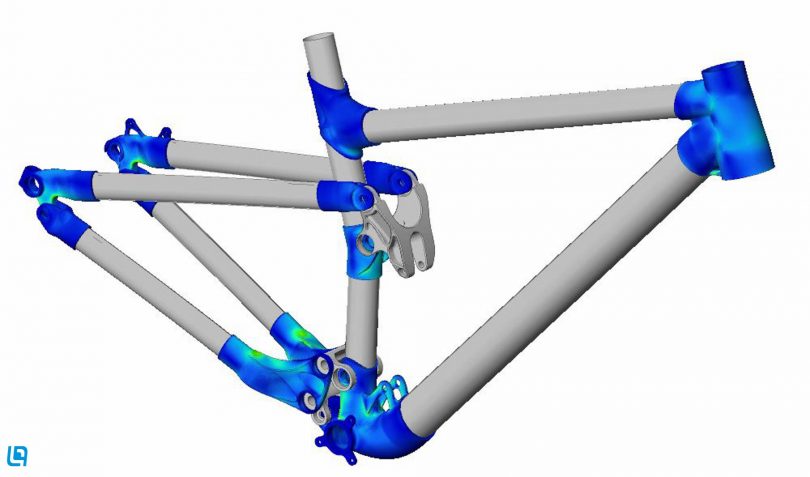

The unique looks of the Robot Bike R160 are down to the mixture of materials used, blending titanium and carbon fibre into one frame. Their experience in the aerospace industry and F1 has shown that composites like carbon fibre work well when shapes and loads are simple, whereas metals work well in areas of high shape complexity and when loads come from different directions. Robot Bike has added high strength to weight titanium in areas of maximum stress and connected them with the carbon fibre tube to keep stiffness high. The joints are moved away from the areas of peak stress and employ double lap shear joints as seen in the aerospace industry.

To get very geeky, Robot Bike has used topology optimisation to create lugs that are optimised for a given set of loads whilst being as light as possible, and through a process of Additive Manufacturing ( a bit like 3D printing), they can now easily be manufactured. This process allows very high control over fatigue, giving Robot Bike the confidence to offer a lifetime warranty to the original owner. When creating the lugs, the process of selective laser melting lays down titanium powder particles which are fused together by a high power fibre laser, and then heat treated for optimum mechanical performance. This printing approach ensures that all the lugs can be created bespoke to order. These processes would more commonly be linked to brands like Airbus, Boeing, GE and Rolls-Royce. Using lugs allow the use of carbon tubes that can be manufactured 100% with unidirectional fibres, and while this does not result in the sculpted ‘carbon look’ it does result in massive strength.

The frame uses a DW6 suspension system developed by Dave Weagle, with a progressive leverage ratio, and a focus on high efficiency, Robot Bike are pushing the R160 as a bike to do everything from long days in the saddle to smashing hard enduro trails.

The R160 uses 27.5” wheels and have thankfully stuck to standards of a 12×142 rear axle and a threaded bottom bracket. The retail price will be around £4,395 with a lead time of 4 weeks, and the frames will be available to order from June 2016.

Our impressions of the Robot Bike Company R160

We have always wondered what an F1 designer could bring to the table when it comes to bike design and now we know. The looks will certainly polarise opinion and the price will, of course, ruffle some feathers, but the proof will be in the riding, and if the R160 can live up to its engineering pedigree then it could well be the best bike on the market. We look forward to testing one.

More details about the Robot Bikes R160 can be found on their website.

Did you enjoy this article? If so, we would be stoked if you decide to support us with a monthly contribution. By becoming a supporter of ENDURO, you will help secure a sustainable future for high-quality mountain bike journalism. Click here to learn more.

Words: Photos: Robot Bike Company