BRIT BITS: EMPIRE CYCLES – Factory Visit

It was a the final round of the UK Gravity Enduro series 2012 when I met Chris Williams, owner of Empire Cycles. Quite a quiet reserved fella, Chris had a stand there, showcasing his Empire MX6 Enduro bike, Chris may not have grabbed my attention immediately, but the bike certainly did. This (last years’ model) had styling, quite unique, with it’s “machined out of a solid block” head stock, swing arm and backbone with lattice effect on the swing-arm. With the frame needing hardly any welds to hold it together, plus it sported a separate seat tower. Being a person who loves the unique “non-run of the mill” stuff, I was drawn to this single swing-arm bike and needed to know more.

Winter was soon upon us then gone, the 2013 season was in full swing and Chris was once again flying the Empire colours at the Enduro races. As I have attended each race I have got to know him quite well and just love his passion towards his brand, being a true perfectionist. Chris started the Empire brand around 6 years ago, with the creation of the very unique AP1 downhill bike, this was his first head turner, being the first cast framed bike out there. Three years ago he got to work on the MX6 Enduro bike, which is still his current model. Each time I saw him at the first three rounds we talked of a factory visit, but it was when he told me of his latest working progress of a pre-production 3D plastic, printed, full size, built up model of the new MX6 Evo, that I realised it had to happen. So it was on a very hot day that we headed up with Vini (readers of Enduro Mag will soon get to know about him) for the viewing of the said proto bike, Vini (Enduro Mag’s new UK trainee champ) was collecting one to try out.

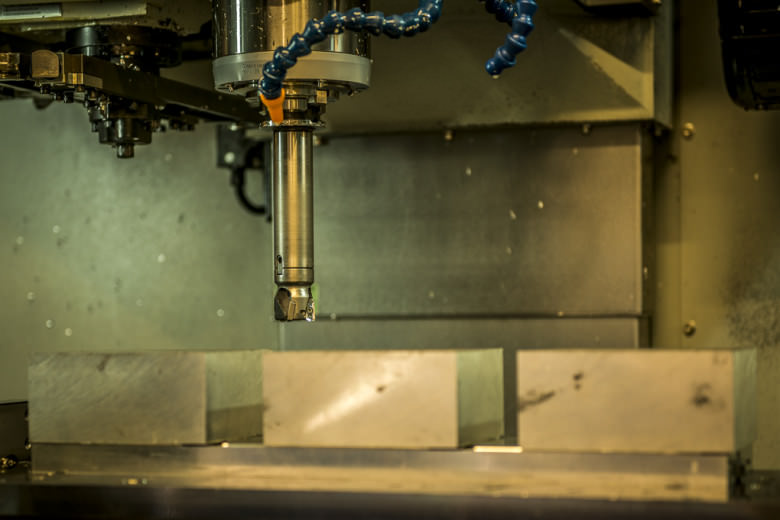

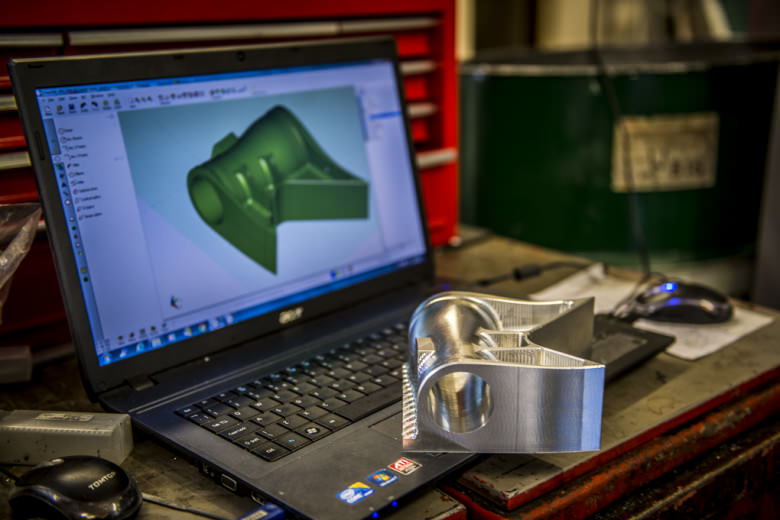

On arrival we were straight into Merlin Engineering in the thick of things, Chris works out of this place in conjunction with their projects, the place is real impressive, with milling machines just seeming to be everywhere, like some kind of weird pods you could imagine some alien being kept in for close observation! Some of the latest headstocks were being milled out as we arrived, it was so hypnotic to watch the large liquid cooled machine as it effortlessly carved out the gorgeous shape of my favourite part of the bike, the head-stock from massive blocks of square alloy. Into the office and we were soon inspecting the 3D plastic printer and shown how it makes perfect models of things using a layering effect; mind blowing stuff, this was one of the machines talked about on the news, people make guns out of these things, crazy! Chris told us of how he has possible plans for a unique but top secret way of working with carbon fibre in future to keep costs down, but the most impressive is his future plans to maybe be the first person in the world to make a 3D printed alloy frame. This technology is so new that only the likes of Formula One teams have access to it right now, but he had one of the head honchos coming to see him about plans for it the following day! Chris informed us of how, when he had a stand up at the Fort William World Cup, Etienne Warnery, the design engineer behind the new GT Fury came over and introduced himself and said that the MX-6 EVO was a beautiful machine. He said it was a highly original design, using manufacturing techniques that he had never seen before. He also said that he would have been extremely pleased to have created such a machine and wished him well with the sales, offering him his contact details so they could stay in touch. What a compliment from a man who has designed such a race winning machine!

We wander through the factory, Doc clicking away on the camera, this place was like a photographers dream to him. There are proper traditional working class British blokes everywhere, machining and scuttling around all with a job to do. I thought this is how a factory should be, no bullshit, no marketing suite or latte machine, just blokes getting on with their job. We then get to the large, kind of bike room, with boxes of lovely new goodies here and there from Empire’s supporting brands, those being Hope, Sram, Rockshox, Renthal and Continental, Chris couldn’t state enough how great it was to have these leading brands offering their support in his projects. There was one of the Beefy AP1’s and a few of last year’s MX6’s, plus lots of frame parts knocking around. But proudly set up on the stand, adorned by camera lighting and a large white background, was the new style 3D Evo bike in all it’s glory! I’d seen the photos of the bike, but they really didn’t do it justice, this was just so British, beautiful unique styling, square tubes and exact copy swing-arm, headstock and bottom bracket housing as is going to be on the finished product. The swing-arm was the most noticeable difference, not being the lattice effect CNC version any more, this down to production cost cutting and the smoother tube style being more suitable for the biking fraternity’s taste. You could tell this was Chris’s baby, as the fragile 3D print has to be manoeuvred very carefully, due to the many small plastic printed parts being glued together and accommodating forks, wheels, bars etc for show purpose only. Close inspection of this bike revealed the bikes hidden gems, the little secrets Chris had kept to himself until now, about how this bike is completely unique.

The main selling point of this frame is how all angles BB height, head angle and seat angle are kept the same when running 26″ or 27 1/2″ by use of three separate frame components. Firstly the rear of the swing-arm can accommodate the wider or narrower width hub by the clever use of separate inner swing-arm removable spacers. Secondly the angles of the swing-arm are changed through the use of differing plates attaching the swing-arm to the bottom of the shock, thus no need also for off-set bushes. but the final and most impressive thing was (totally unique to this bike) the Hope-made fork spacer, to fit under the head-stock and accommodate the 26″ forks, as the front end naturally accommodates the 27 1/2″ forks without running the spacer, this keeps the head angle the same running either wheel sizes and forks. Plus with the head-stock being made to fit the large internal headset, angles can be changed from 66.6 degrees if desired with the use of an angleset. So as Chris says “This means that the frame really is a genuine upgrade if you have a 26′” wheel set up and plan on going bigger wheels in the future. Other manufacturers are now offering new frames as an upgrade but only as a 27 1/2″ set up, so what exactly are they aiming to upgrade?!” As for other angles they are are 31.6mm seat tube, 12m Maxel, 66.5 degree head angle.

When it comes to the current situation of the new frame, well its a long laborious process, as with all product development, the headstocks are milled in house, but the patterns have to be made to make the rest of the frame. These tools are currently over at the foundry being tested and re-tested to make sure they do their job. Then between a couple of other places in the country the separate components of the frame will be made, then sent to Chris to be welded together, then undergo more rigorous strength testing and x-raying. Then and only then, when Chris the ultra-perfectionist is happy, will the first one be going out into the hands of yours truly for my Brit Bike Build article and to be tested in real race situations, to say I’m excited about having the first one is an understatement! Once up and running with a finished product Chris, in conjunction with Merlin Engineering and the other UK businesses involved will have the capabilities to produce a great number of bikes.

PRICES FOR THE MX6 EVO FRAME

- Rockshox Monarch RT3 £1246

- Rockshox Monarch Plus £1399

- Cane Creek DB Air £1499

- Cane Creek DB Coil £1499

COMPLETE BIKE build starts at £2499

Words: Jim Buchanan Photos: Doc Ward (http://www.doc-photography.com/)

Did you enjoy this article? If so, we would be stoked if you decide to support us with a monthly contribution. By becoming a supporter of ENDURO, you will help secure a sustainable future for high-quality mountain bike journalism. Click here to learn more.