On Location | Following An Order Through Chain Reaction Cycles

Ever wondered what goes on behind the warehouse doors at the world’s biggest online bike shop? Two days from finishing our amazing tour of Ireland we were riding around the city of Belfast and Jims bottom bracket started making some horrific cracking noises, we dubbed it the ‘rice crispy bike’. His Bottom bracket was knackered, so we headed off to Chain Reaction Cycles warehouse in Doagh to get a new one and check out the different processes between ordering a bottom bracket and it arriving at your house.

Chain Reaction Cycles ship to over 110 countries each week from Paraguay to Vietnam, they stock over 70,000 different product’s sending over 175,000 orders each month. With 155,000 individual items being picked each week, that’s over 8,000,000 parts a year; Crazy! CRC have managed to keep their error rate down to only 0.2%, a very impressive figure considering how many packages they handle.

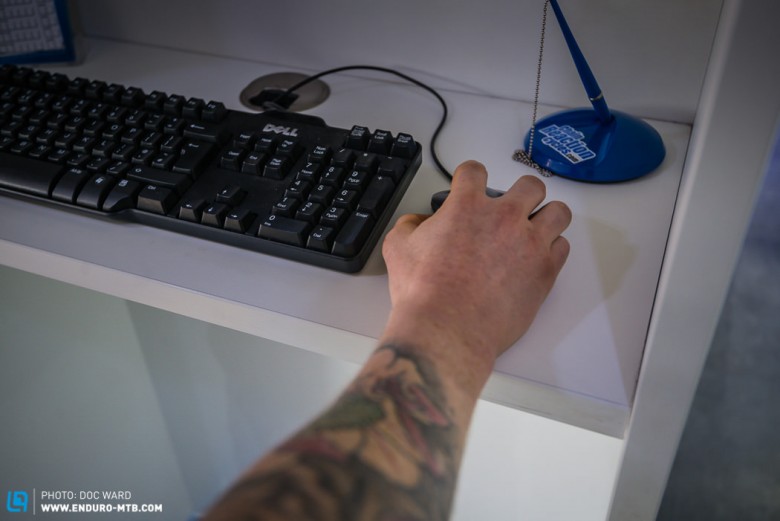

Step 1

First things first, we needed to order a bottom bracket, CRC have a large showroom with computers at hand where we could order the BB on site.

Step 2

The order is downloaded to CRCs internal systems from the website, it then passes through authorization (including fraud checks) and either goes into the warehouse management system or gets checked over by a security team in customer operation’s.

Step 3

The order then gets sent over to CRCs warehouse management system (WMS), this is the brain of the warehouse, it manages everything from what order to pick parts, to splitting up complete and incomplete orders. The BB placed into the system by warehouse and location, if you chose to pay for priority pick this is where your order is bumped up.

Step 4

The bottom bracket is now ready to be hand-picked, the picker wears a headset which supplies voice instructions about what component needs picking to either start an order or consolidate an order. The WMS gives the picker a specific order to pick different parts from to minimize wasting time walking around the massive warehouse. The picker scans the barcode so the system knows it has been picked.

Step 5

The BB goes into the packing area, ‘uglies’ and small items go to the manual pack area, everything else goes through the automatic packaging machines were they have only 2 choices of boxes, either small or large. The WMS will split up unfinished orders and send them to consolidation.

Step 6

The packaging machines scan the barcodes on the boxes which identifies the height of the content, the machine then scores and compresses the box to suit the sizing of the content, keeping the boxes as compact as possible. A lid is then automatically put on followed by the address label.

Step 7

The packages from both the manual and the automated packaging areas head down the rollers to the backdoor. Here they are split up into the correct postage area for distribution by the couriers ready to be excitedly opened by the customer.

So there you go, it turns out things aren’t flown around by magical fairies, there’s a lot of different processes, intelligent software and teamwork to get your parts delivered. Our tour guide Sandra Pryce puts a massive emphasis on continual improvement and customer satisfaction, something that can clearly be seen after our visit.

Words: Andrew Cooper

Photos: DOC Ward

Did you enjoy this article? If so, we would be stoked if you decide to support us with a monthly contribution. By becoming a supporter of ENDURO, you will help secure a sustainable future for high-quality mountain bike journalism. Click here to learn more.