Exclusive | The Sentinel – is this the future of fork seals?

The Kickstarter-campaign for the Sentinel fork seals by Dämpferklinik from Tübingen has already been introduced by us and been discussed at length. There are 29 days left to back this project on Kickstarter.

The Inventors

The Dämpferklinik in Tübingen is a small but excellent workshop which has been carrying out on-site service and tuning for suspension components for the past eight years. With increasing popularity the company’s range of machinery has grown, and therefore they were able to produce more and more tools and small parts by themselves or purchase them from top-quality component suppliers to achieve the best possible performance of forks and shocks.

The functionality of traditional dust wipers on suspension forks has been bothering the owners Steffen Dittmar and Melanie Keding for some time now. After a couple of inquiries by various customers the two of them decided to search for a better solution – Steffens bachelor-degree in chemistry was of great help, already providing him with knowledge of the material science. The outcome of these endeavours is the Sentinel, which can be co-financed by everyone via Kickstarter.

The Sentinel – How it works

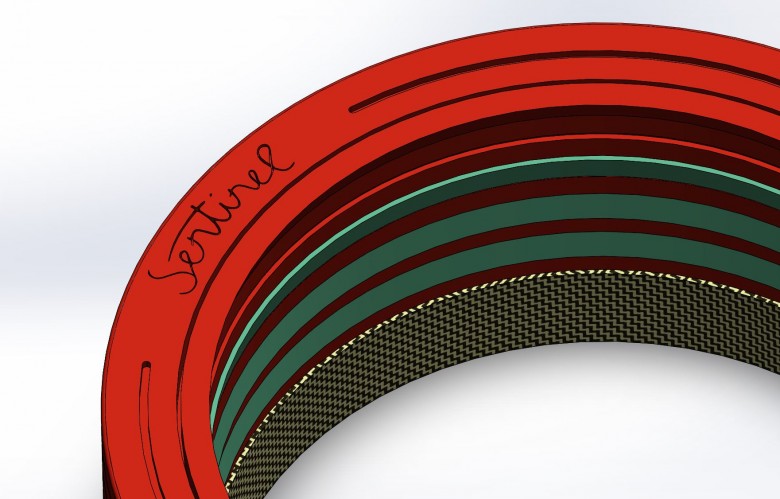

The biggest disadvantage of the current fork seals is that they produce very high friction which is a frequently underestimated negative effect on the responding behaviour of suspension forks. This is why from the beginning it was clear that a much improved performance can only be achieved when the conventional material rubber can be substituted with a high-quality low-friction polymer. But this is only possible through a change of the design into a two-part construction.

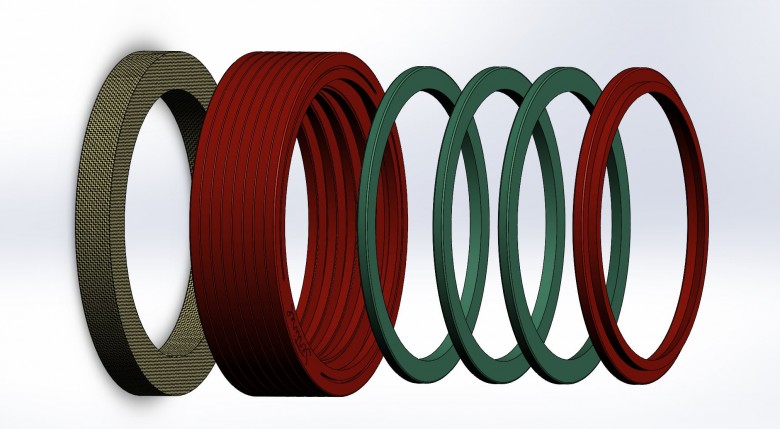

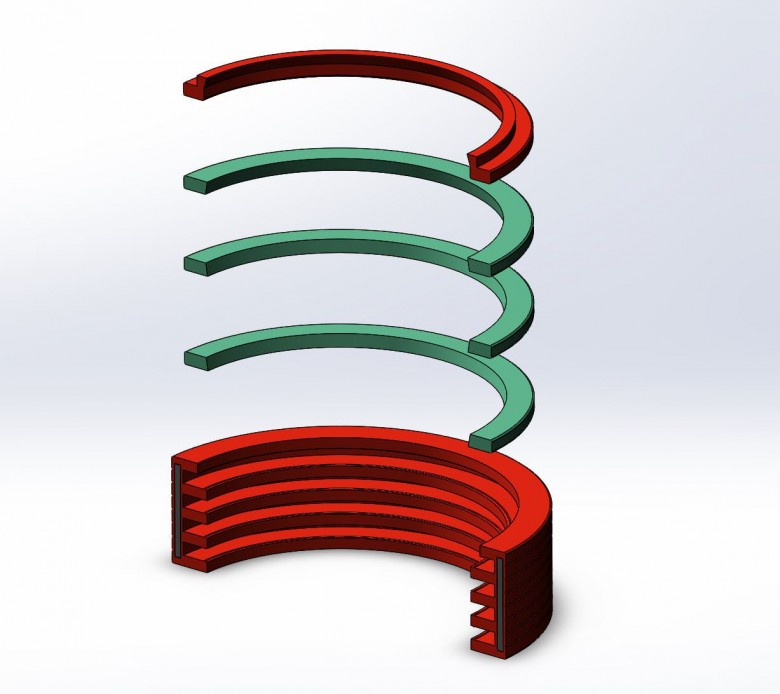

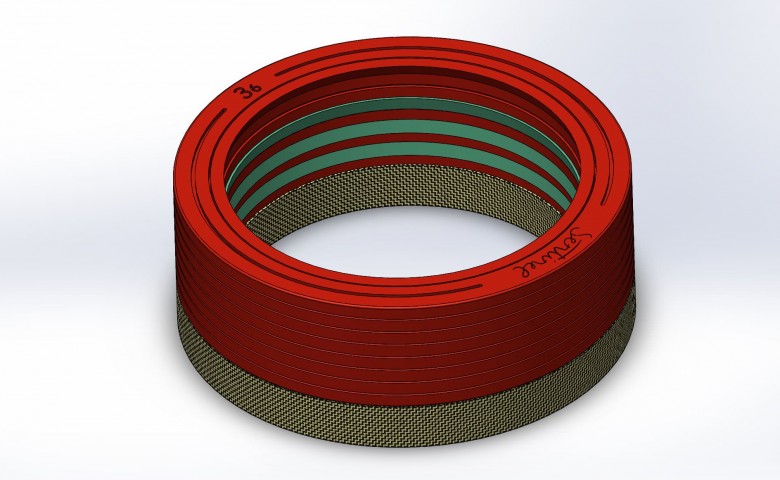

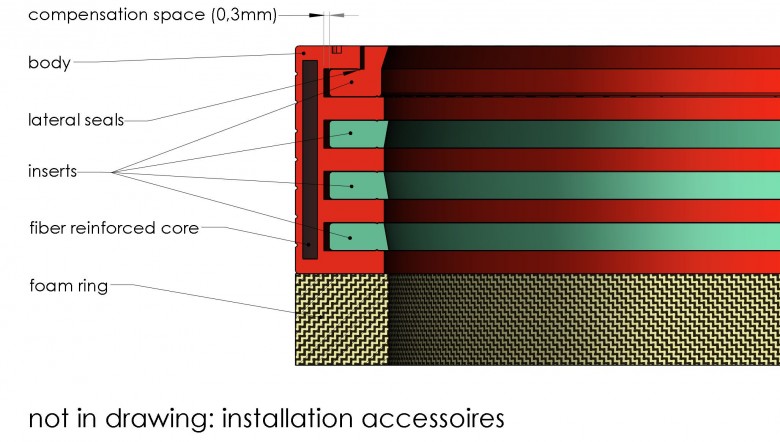

The final outcome was the multi-part construction of the Sentinel. The movability of the inserts in the body can equalize fabrication tolerances in the fork. A built-in reinforced ring ensures that it stays in form and sits firmly in the fork. At the same time up to four inserts are applied which take on the actual job of the component, which is the sealing of the fork. All four are snugged into the body where they are sealed off by small lateral seals. The upmost insert which seals off towards the outside is formed like a L and thus also seals off at the top with the body to prevent the entrance of dirt or water.

Both the body and the inserts are made out of PU (polyurethane), a polymer which can be exactly adjusted to the destined area of application. Because of the different tasks they have to fulfill the separate components are manufactured from respectively optimized types of PU.

Function of the body

The body is elastic enough to be easily installed into the fork. The coated, fiber reinforced ring firmly fixates the body in the fork. The entry for the first insert is open towards the top, so that the ring shuts off with the top side of the body. A 0.3mm wide gap results with which the insert can firmly seal off with the body.

Function of the inserts

Of course the question arises why exactly four inserts are applied. A pair of each take on one task: The upper two keep dirt and fluids out of the fork, the lower two ensure that the lubricating oil stays inside the fork.

One insert for each intended use would actually suffice. But to be absolutely secure one is inserted to take on the task whereas the second one adds an extra level of protection, in case tiniest dirt particles should have entered, as is the case with every seal. If one wants to optimise the fork towards the best bump sensitivity possible, e.g. for racing, this can also easily be rode simply with only two inserts, of which one seals towards the outside and one towards the inside.

All inserts sit in grooves and are sealed off with the help of small lateral seals. Through the mobility of the inserts inside the grooves they can shift slightly in so far that they can compensate tolerances. Also, the lateral seals prohibit dirt or oil from pushing behind the inserts and thus reach a spot where they don’t belong.

The inserts sit closely in a defined angle next to the stanchion, so that they seal off as effectively as possible in the respective direction and at the same time create a negligible friction.

The upmost insert holds most of the dirt outside. To ensure that it doesn’t stick between the body and the inserts this insert seals off levelly with the body, so that held-off dirt simply slides off outwards. With the help of lateral seals this insert is sealed off against dirt that could be pushed around the insert.

Production

The manufacture of the Sentinel Wipers will happen completely in Germany, more precisely in the Dämpferklinik itself. For this a Boy 22 E injection moulding machine comes into operation, with which all parts can be directly produced. Thereby a modification of the products at short notice is always possible, because all the other tools and machines are on site for a modification of the injection moulding machine – therefore the Dämpferklinik is independent and flexible.

The Kickstarter Campaign

When the concept was clear the question came up how the two inventors should finance the project. The problem was that although the production with the injection moulding machine doesn’t create high costs you first need moulds which enable the manufacture. The fabrication of these moulds is the actual, high cost factor, which is supposed to be covered primarily with the help of the Kickstarter campaign.

The Sentinel Wipers are also supposed to be available for all common fork models, so that several moulds are necessary for every stanchion diameter. Because the production costs weren’t possible to manage on their own, Steffen and Melanie decided to gather the necessary funds via Kickstarter.

The advantage of Kickstarter hereby is that the supporters only then have expenses when the expressed goal is reached.

More information about the project at Kickstarter and at the Website of the Dämpferklinik.

Words: Martin Stöckl Pictures: Klaus Kneist

Did you enjoy this article? If so, we would be stoked if you decide to support us with a monthly contribution. By becoming a supporter of ENDURO, you will help secure a sustainable future for high-quality mountain bike journalism. Click here to learn more.