Helicopters, supercars and bikes – situated between France and Spain, sits the small bike brand Forestal, who have dedicated themselves to the development of high-tech ebikes. We visited the exotic and extravagant bike brand and had a look behind the scenes for you.

Ever since its foundation, the brand from Andorra and the legendary story of the company’s origins involving a Belarusian investor have been surrounded by mystique. A lot was announced, but for a long time no products were available. Malicious tongues claim that Forestal do not even exist. We had the opportunity to test the Siryon light eMTB in our big comparison test and were quite impressed – however, we still wanted to find out who and what is really behind it.

In a small country before our time…

In the middle of the Pyrenees lies the Principality of Andorra. The small country in the midst of mountains between Spain and France is known above all for its many kilometres of ski slopes. It is one of the smallest countries in Europe and barely larger than the capital Andorra La Vella, where the HQ of Forestal is based. Due to the limited space available, the houses here grow upwards rather than outwards. Finding the Forestal company building is like looking for a needle in a haystack, and Forestal make use of what is already there: An old car dealership serves as their development and production site with the faded logo of a major car manufacturer still emblazoned on the wall. It’s all quite inconspicuous, only a small showroom and a black garage door with the company logo reveal what is going on behind the thick concrete walls. We paid a visit to Forestal to shed some light on the mystery.

What do supercars and helicopters that turn into drones have to do with eMTBs?

The black gate conceals parking spaces inside the building because space for parking is as scarce in the city as building space. Forestal’s company building is built like a multi-storey car park, with access ramps leading from floor to floor. There are a total of six floors, which can also be reached via a lift and stairs – it’s quite easy to get lost, to be honest! Luckily, we have Saša to pick us up and guide us through the cool and somewhat sterile-looking rooms. On the very first floor, a surprise already awaits us: Next to eMTBs, we encounter helicopters. Before we even start to talk about Forestal, we cannot stop ourselves from asking what on earth do helicopters have to do with the development of ebikes? The simple and matter-of-fact answer is that the owner is planning to offer taxi flights with converted helicopter drones for special guests and is therefore tinkering with helicopters in the Forestal company building. Exciting, but the small helicopters do not really inspire confidence and it’s quickly becoming obvious that Forestal are different. Earlier that morning we went for a quick visit with old friends from COMMENCAL, who are also based in Andorra – but the differences couldn’t be more evident. While COMMENCAL have grown from the core of the scene over decades, Forestal were built with a lot of money in a very short time. You can feel and see this immediately in the way that employees in these companies interact with each other, in the company buildings, and in the respective company cultures – which is not really tangible yet at Forestal – but also in the conception of the products.

We don’t get to meet the Belarusian tech millionaire, but according to the Forestal team, he rides bikes himself and is said to have made his money in the IT and gaming industries. He is not involved in day-to-day operations and prefers to stay in the background as investor and inspirational input.

In the former car dealership, the production winds whimsically upwards via dark ramps. In the vertically-structured company, a different work step takes place on each floor: from R&D downstairs to assembly and shipping on the 3rd floor. No matter on which level the ramp spits us out, we are surrounded by cool concrete walls bathed in artificial light. Depending on the floor, the flair and interaction of the staff varies from open and friendly to duty-oriented and isolated. There seems to be little interaction between the floors. We have an impression that a stronger corporate culture and places for exchange and meeting across all floors would do Forestal a lot of good. The best example is the spartan kitchen on the lowest floor, which fulfils basic nutritional needs, but doesn’t necessarily promote social gathering.

From the beginning – The development process at Forestal

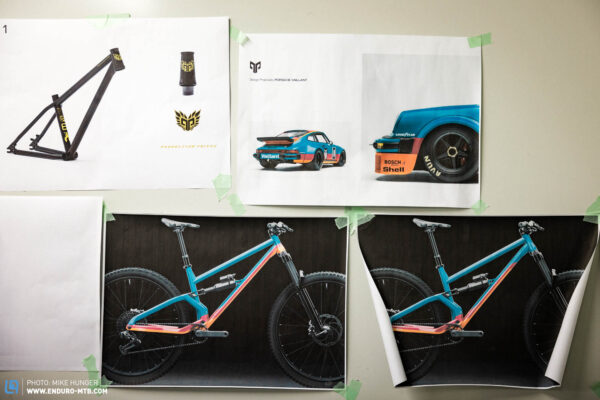

The entire development of Forestal takes place in-house: of the 55 employees, 15 people are responsible for the development process. When it comes to design, the Forestal founder likes to have his say and set challenges for the designers. Brand sneakers, concept cars, even aeroplanes – the design of a wide variety of products that the owner likes must find their way into the colours and shapes of the bikes. The Forestal bikes look really cool and stylish – so somehow this process works, chapeau!

The design process is followed by building a prototype. The bikes are first made of steel and after conducting a few tests transferred to the carbon mould. At first glance, the rather rustic steel frame is reminiscent of Frankenstein’s bike, but thanks to various adjustment options, it combines frame sizes M and L in one bike. Different headset cups also allow for different head tube angles. The test laboratory contains numerous pieces of equipment for testing materials, and this is where the endurance tests of the frames as well as the tensile and compression tests are done. While you see this kind of equipment at some bike brands, everything that followed in the next few rooms is extremely rare in the bike industry. Forestal do most of the development of the drive system itself. They have taken on the mammoth task of developing their own complete concept right from the start instead of just buying an already existing motor system and integrating it into the frame with a few adjustments. Respect! Though, it is obvious that the risk and effort are amplified. Another challenge was that much of the development time coincided with the pandemic, and trips to Asia or face-to-face meetings were not possible, or very limited. The idea of going straight for a light eMTB was also quite progressive at the time.

BAFANG build the motors on commission exactly to Forestal’s specification and were the only motor manufacturer who were interested and had sufficient production capacity for the young and at that time still unknown bike company. After all, there is still a difference if a well-funded start-up like Forestal or an established billion-dollar company like Specialized come knocking on a motor manufacturer’s door and want a custom production.

Forestal then built the frame around the motor, which boasts a low total weight of 1.9 kg thanks to the titanium parts and magnesium housing.

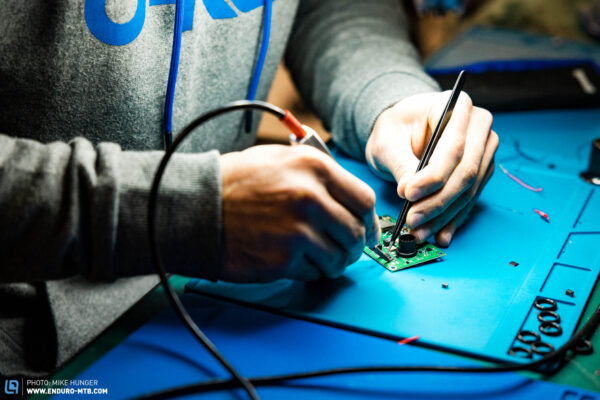

The depth of the development is impressive. Not only are the motor and battery system developed in-house, but so is the rest of the electronics found on the bike, such as the colour display, GPS device and circuit board, including both software and firmware. The prototypes of the circuit boards for the large touch-sensitive display, which runs on Android, are soldered on site before they go into production. Thanks to the integrated eSIM card, the display fitted into the top tube comes with an extensive range of functions such as navigation, training and riding modes as well as anti-theft protection. In the future, a lithium polymer battery will also be integrated in the head unit so that the bike, in the event of theft, can be located even if the main battery is disconnected. A simpler version without connectivity and without a display will also be launched on the market in the future.

Production Privée – A factory within a factory

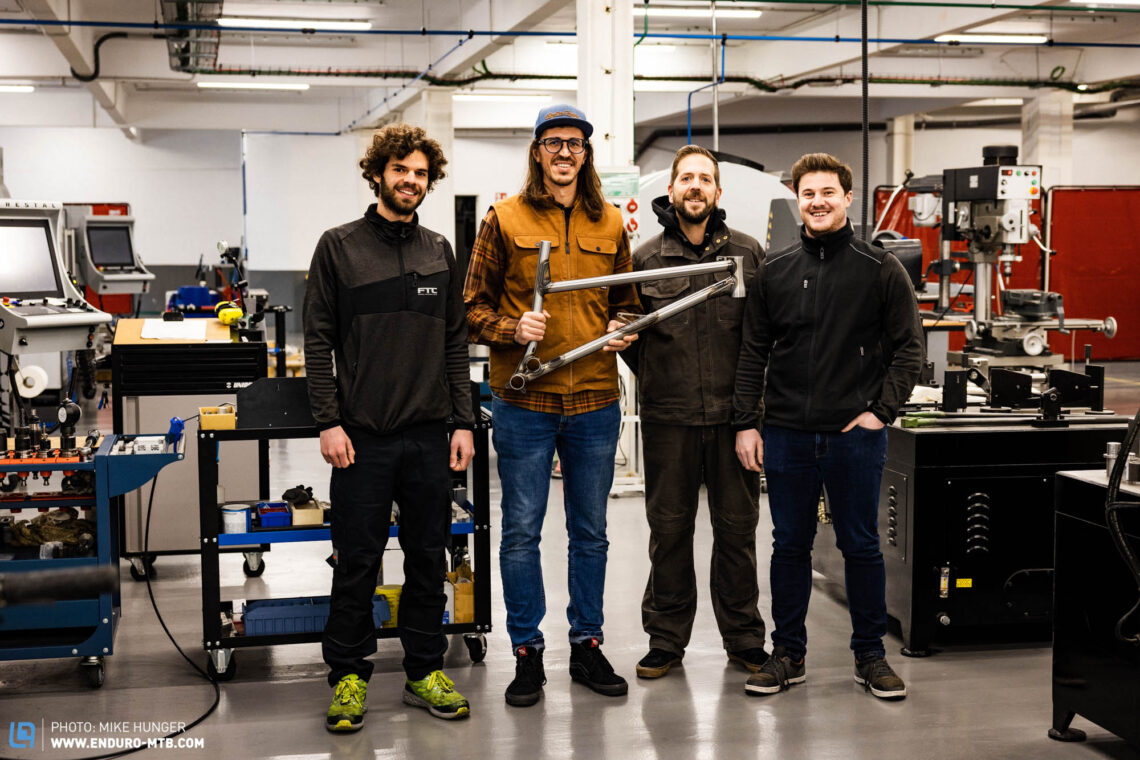

Two floors above the development department are the manufacturers of Production Privée, dedicated to the development and production of bikes and components with cutting-edge manufacturing methods. The Andorian bike manufacturer were bought by Forestal in 2020, including its employees and founder, and the two companies now work closely together.

Among other things, the Production Privée team is conducting research into thermoplastic frame construction. The material they’re using is called Peek, which is mainly found in the aerospace industry. The dry laminate is cut and positioned by a robot and then hardened with resin. The frames are not made from a single piece, but from two halves, which are then glued together. The first prototypes were developed and produced in collaboration with the University of Aachen and a manufacturer of sports car carbon rims, but the goal is to produce their own carbon frames in Andorra. The advantage of thermoplastic composite technology is that the manufacturing process allows for 90% of the process to be automated, meaning that theoretically 8,000 frames could be produced with only eight employees. In addition, thermoplastics are more recyclable than classic carbon frames, which once produced cannot be easily recycled and are therefore virtually special waste. Thermoplastic carbon frames, on the other hand, can be simply remelted or reshaped under heat.

In addition to research on the thermoplastic method, Production Privée also produce frames made of steel and titanium, so a giant welding robot that can weld steel frames automatically occupies their hall. This process allows for consistent high quality, clean seams and enables three frames to be welded in 12 minutes. The CMT (Cold Metal Transfer) welding technique is designed to eliminate the need to treat the welded frames again. One of the Production Privée bikes goes by the name of Shan No. 5, and in its third iteration combines a steel main frame with a carbon rear triangle. Compared to a steel rear triangle, the weight is almost halved from 1.6 kg to 850 g and the finished bike with robust DH tires is claimed to weigh just 15 kg. They are also experimenting with steel and alloy frames by bonding them together. Here you can clearly see the great interest in research and experimental use of new and innovative production methods and materials.

It’s getting colourful – Paintwork and assembly in-house

Colour plays a major role, which is why the paintwork at Forestal was inspired by various light phenomena and is named Halo, Neon or Diode, for example. In their configurator, you can choose from many options or put together your own custom paint job. For example, you have the option of the bike being custom painted in the colour of your car. The paint shop occupies an entire floor in the Forestal facility and was relocated from Taiwan to Andorra during Covid. They set it all up there and due to the pandemic, all the painters had to be trained without the supplier’s help. Preparing the frame for the paintwork alone takes a lot of time and effort, as it has to be sanded for 1.5 hours before the painting process can be started.

The frame is then primed and sanded again for another 1.5 hours before up to six final coats of paint are applied. As with hypercars, the paintwork is polished and checked by hand at the end. Every day, up to ten frames leave the paint shop mostly with a customised paint finish.

The bikes are then assembled on the floor above. The matching components of the respective bike are prepared beforehand in the warehouse and come ready for assembly. So all the parts, such as the steering tube or the chain, already have the right length, making installation quicker and easier. Assembling a bike takes around four hours and, as with AMG motor construction, one mechanic is responsible for an entire bike. We looked, but we couldn’t find a plate with the builder’s signature though ;).

Checking out Marc Busquets’ Forestal Cyon bike

As a treat, we had a closer look at the private bike of lead developer Marc Busquets. He has built it with high-end parts and unique details and thus made his (and many a rider’s) dream come true.

Conclusion

The depths to which Forestal have gone in terms of development are impressive, and on top of that they’re researching innovative manufacturing methods and projects together with Production Privée. Much of the work, such as development, painting and assembly, is done at the HQ in Andorra and is undeniably exceptional. Despite some ambiguity about the background of the company and the lack of a vibrant corporate culture, we salute the team in Andorra for what they have achieved in just a few years, creating something quite extraordinary!

You can find out more about at Forestal.com

Did you enjoy this article? If so, we would be stoked if you decide to support us with a monthly contribution. By becoming a supporter of ENDURO, you will help secure a sustainable future for high-quality mountain bike journalism. Click here to learn more.

Words & Photos: Mike Hunger