First Look | Hope Technology Cranks

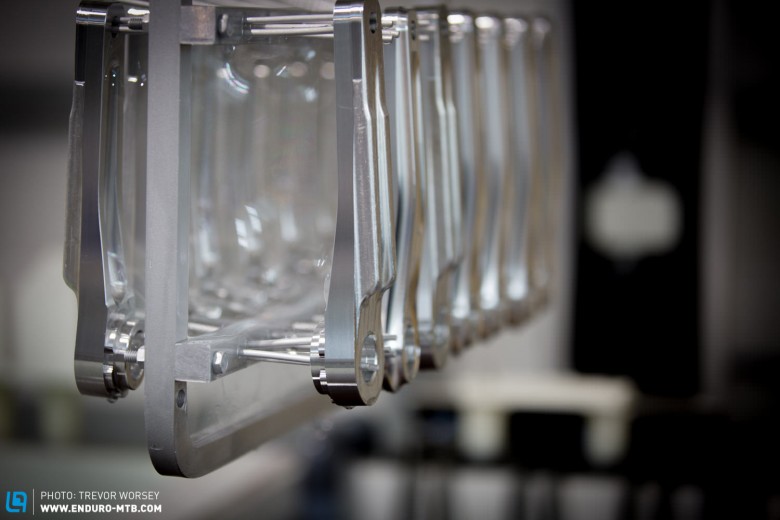

At long last Hope have finally started production of their eagerly anticipated cranks. We brought you news of these at Eurobike, and after a long wait Hope’s in-house CNC machines have been fired up, and are now busy turning raw aluminum ingots into these beautiful cranks.

Developed over many years the Hope crank has been designed using the latest FEA (Finite Element Analysis) tools and extensive multi discipline field testing. The cranks feature a unique expanding spline axle/arm interface (pat pending). Previously, cranks using splines often used a taper to ensure a snug fit. These cranks worked fine the first time they were fitted to the axle, but once they’d been taken off and on a few times, the spline became worn, so they’d suffer from the inevitable movement and annoying creak. Hope felt there must be a better way.

After many years of testing they think they’ve found it in the form of an expanding spline. The cranks are pulled onto a conventional spline, then a tapered plug is fitted inside the axle which can be tightened up each time the arm is refitted – giving a perfect fit every time. Added to this Hope CNC machine the arms from forgings which gives them immense stiffness and strength. The arms also have a splined mounting for spiders and direct mount sprockets giving excellent versatility. The cranks are compatible with the majority of bottom bracket systems via Hopes expanded range of bottom brackets.

Specifications:

- Material – Forged and CNC machined 7000 series aluminium alloy crank arms

- Length – 165, 170 and 175mm Q-Factor – 167mm

- Axle Diameter – 30mm

- 3-piece construction with expanding spline crank arm/axle interface (pat pending)

- Versatile Spline mount compatible with 26T to 36T 104BCD and Double 64/104BCD

- Colours: Initially black, with red, blue, silver, gunsmoke and purple following in March

- Weight: 641g (arms, axle and 34t spiderless ring)

Prices:

- Arms, Axle and Spider £245/€300/$429.50 Arms and Axle £215/€265/$375

- Spider £40/€50/$70

- Spiderless Retainer Chainring £55/€68/$95

For more information check out the Hope website.

ENDURO Impressions

From the moment we first saw them, we have been looking forward to building these cranks up, and are very impressed with the quality of fit and finish. At 641g with the spider-less 34T ring they are competitively light and offer great compatibility. We have been putting these to the test through a grimy UK winter so expect a full review soon!

Did you enjoy this article? If so, we would be stoked if you decide to support us with a monthly contribution. By becoming a supporter of ENDURO, you will help secure a sustainable future for high-quality mountain bike journalism. Click here to learn more.