First Look: The revolutionary electronic Shimano XTR Di2

As part of the UCI XC World Cup in Albstadt, Shimano introduced the first electronic component group for the mountain biking sector, the XTR Di2 (M9050). The XTR Di2 adds to the already presented recently mechanical XTR M9000.

It’s already been a long time that rumors talked about an electronic Shimano XTR Group. As of 2008, when Dura-Ace Di2 came on the market, people had already counted on a mountain bike specific XTR model following.

In fact, now it is here, the new Shimano XTR Di2. Overall, it has taken longer than expected. It was an over 3 year period, of work specifically on the electronic group. The main challenges from adopting of the road group, was to achieve a very stable and robust switching performance.

The Shadow+ Technology should be used too. That’s why there is presupposed a more powerful engine which has correspondingly more battery consumption.

The main advantages of Di2 platform compared to the mechanical switching system are extremely precise and fast switching. Shifting requires significantly less effort and success literally at your fingertips.

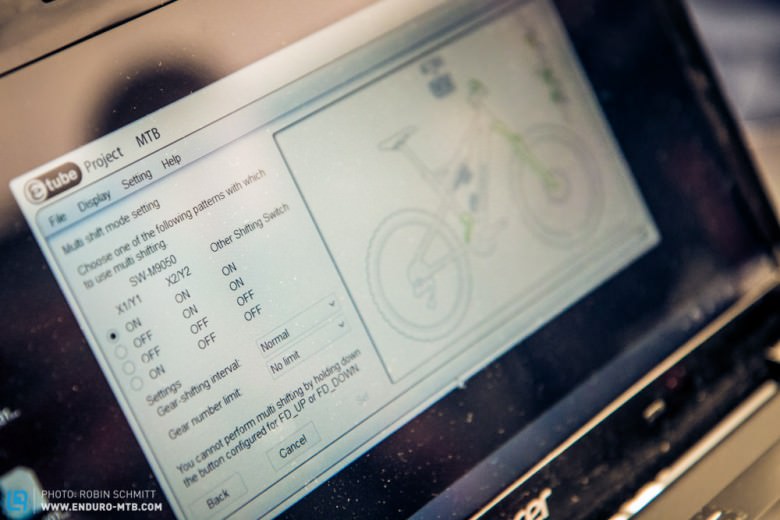

The peculiarity of the electronic shifting group and especially the biggest difference to the mechanical version is the programmability of the entire system. So you can customize the XTR Di2 on the individual riding style and personal preference.

Basis of this programmability is the E-Tube platform which is already used at the Di2 road bike group. All cable of the Di2 components are networked via plug-and-play connections and all receive their power from the same battery. This one is either positioned in the seatpost or the stem (steerer).

In order to integrate the sensitive cable more and protect it, Shimano offers special components of their own PRO component line. For example, the cables disappear in the recesses of the handlebar.

Thanks to the E-tube system, the individual switch buttons allow different switching functions. For example, you can put the control of the front derailleur from the left on the right switch or the rear derailleur to the left switch. Also, there is the multi-shift function, which is activated when the switch is held down. So you can select the switching speed and the number of switched gears (one gear, two courses or even the entire 11 laps).

One advantage of electronic cable system is also the decreased susceptibility to functional impairments of mechanical shift cables like train-elongation or corrosion. But all components still must be connected by a cable to the control and power supply.

The Synchro-Shift option is a special feature of the XTR Di2, which allows the front derailleur and rear derailleur to be controlled by only one switch. In this case, the front derailleur always recognizes the position of the rear derailleur and automatically performs appropriate switching processes from the front to ensure the optimal translation and an ideal chain line. This will also relieve the rider, because he must look for his front derailleur and can be focused 100 % on the track.

There are two pre-installed switching layouts for Synchro Shift. With the E-tube system, the synchro-shift modes can be changed however the rider wants it and even personal switching layouts are possible. During the ride it can be switched back and forth between the two synchro-shift modes and the manual mode.

The following video explains the Synchro-Shift function:

The center of the XTR Di2 system is the digital display that shows important information like the battery charge, gear position, switch mode (Manual or Synchro) and suspension mode. A selection button on the display housing also allows the selection of the desired switching mode – Synchro 1, sync 2 or Manual.

In addition, the display unit is used as a charging port for battery and as a connection port for the E-Tube software.

An other intelligent features of the XTR Di2 is the auto-trim function of the front derailleur. So it takes the correct position for each chainring with all gear combinations.

In case of a crash or a bent derailleur hanger, the rear derailleur has the opportunity to realign again.

Weights

- Front derailleur: (FD-M9070 D-Type): 115 Gramm

- Rear derailleur (RD-M9050-GS): 289 Gramm

- System-Display (SC-M9050): 30 Gramm

- Switches (SW-M9050): 64 Gramm

Bottom Line: The new Shimano XTR Di2 offers a great potential in the direction of smart bike systems. On the one hand it is of course a very expensive and complex technology, on the other hand, it can offer the user many advantages by automating and taking over functions and how information is processed. We will certainly see more connections of bike components and equipment in the future.

The look and feel of the entire switching group is very high, which can be expected at the high price the group will have (probably about 40% more expensive than a mechanical XTR). The challenge, and despite of the many cables, was to achieve a clean look, and was well mastered by the clever integration into the PRO components.

The real Innovation is in the auto adjustment functions of the individual components as well as the synchro-shift modes, which offers a completely new experience and switching logic.

Our Review with practice impressions will follow soon! Preliminary a first impression of the sound and look of the Shimano XTR Di2 :

Shimano XTR Di2 First Impression from WWW.ENDURO-MTB.COM on Vimeo.

Words & Pictures: Robin Schmitt

Did you enjoy this article? If so, we would be stoked if you decide to support us with a monthly contribution. By becoming a supporter of ENDURO, you will help secure a sustainable future for high-quality mountain bike journalism. Click here to learn more.